Pouch type: doypack, flat pouch, zipper pouch, spouted pouch, 3-4 side sealing, shaped pouch, flat bottom pouch

Filling volume: 30-8000 ml

Packaging speed: ≤45 bpm

Application: suitable for food, chemical, daily chemical, cosmetics and other industries of small and medium-sized high quality packaging requipments.

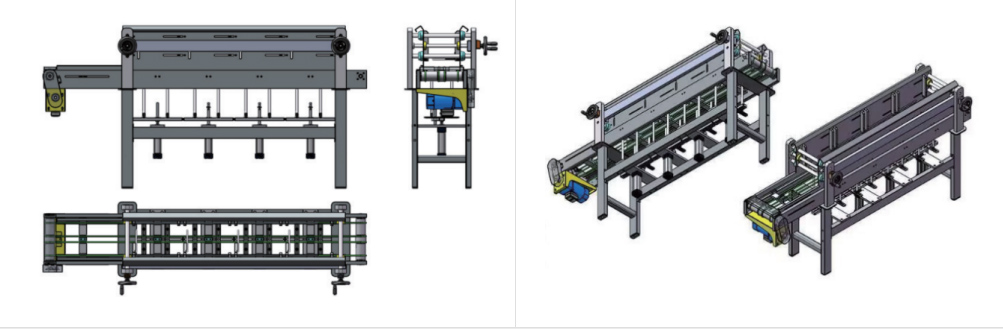

The main body of the packing machine with pre made pouches feeding belt is made of 304 stainless steel, which is beautiful and generous, small in floor space, light in weight and easy to move. According to the actual production situation, customers can add pre made pouches feeding belt, which can place 800-1600 bags at a time, reducing the number of manual bagging and improving work efficiency.

The adjustable conveying width can adapt to a variety of different specifications of bag sorting, and the variable frequency adjustable speed motor can freely change the paging speed within a certain range according to the packaging requirements. It is an essential device for your efficient packaging production.

In particular, this product is used as a supporting bag feeding machine, a self-supporting bag feeding machine, a product understanding of the prefabricated bag packaging machine/bag feeding machine, a horizontal film packaging machine, a horizontal self-supporting bag packaging machine, and a double-outlet equipment packaging machine

|

| The bag magazine is designed with a height of 350 mm, while the width and length are adjustable. |

| The maximum bag thickness is 1.9 mm. Each magazine holds 137 bags, and four magazines can store a total of 548 bags at once. |

| The four-magazine feeding system consists of independent bag magazines, bag-picking cylinders, a servo motor, O-type conveyor belts, adjustment mechanisms, and the machine frame. |

| Each magazine is individually controlled, and the bag-picking action is completed by a cylinder. |

| When all the bags in the front magazine have been picked, a photoelectric sensor detects this, and the next magazine starts feeding. This process continues sequentially. The servo motor drives the O-type conveyor belt to deliver the pre-made bags to the designated position. |

| The adjustment mechanism allows the width to be adjusted according to the size of the pre-made bags via a handwheel and guide plates. |

| Model | 180G-F | 210G-F | 240G-F | 280G-F | 330G-F | 400G-F | 460G-F | |

|---|---|---|---|---|---|---|---|---|

| Pouch Size(mm) | Min | 90*140 | 90*140 | 90*140 | 120*140 | 120*140 | 150*140 | 150*140 |

| Max | 180*300 | 210*350 | 240*350 | 280*400 | 330*500 | 380*500 | 440*500 | |

| Fillling Volume | ml | 1000 | 1500 | 2000 | 3000 | 5000 | 7000 | 8000 |

| Packaging Speed | ppm | ≤45 | ≤45 | ≤45 | ≤45 | ≤45 | ≤40 | ≤40 |

| Machine Size | mm | 2400*2400*1400 | 2550*2600*1400 | 2880*2600*1400 | 3200*2600*1500 | 3520*2600*1600 | 4400*2600*1400 | 4900*2600*1400 |

| Machine Weight | kg | 1100 | 1200 | 1400 | 1500 | 2500 | 3000 | 3500 |

| Power | kw | 3.5 | 4.5 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 |

| Air Consumption | l/min | 400 | 400 | 450 | 450 | 500 | 550 | 550 |

If you are interested in HUAPACK packaging machine, please contact us via

email: info@huapackgroup.com or send your inquiry in the form below.we will reply you within 24 hours.

Privacy Policy Copyright © 2021 Shanghai Huacheng Packing Machinery Co., Ltd.