Pouch type: doypack, flat pouch, zipper pouch, spouted pouch, 3-4 side sealing, shaped pouch, flat bottom pouch

Filling volume: 30-4000 ml

Packaging speed: 60-180 bpm

Application: suitable for food, chemical, daily chemical, cosmetics and other industries of small and medium-sized high quality packaging requipments.

The horizontal packaging machine is a high-quality packaging machine with fast packaging speed, and can also achieve three-side sealing, four-side sealing bag type flat bags, zipper bags, etc. , solid materials and other packaging requirements, equipped with flexible processing stations, which can automatically take bags, open bags, detect, fill, seal and other packaging processes. The bag-feeding model series is an economical and reasonable packaging choice.

The bag feeder series is suitable for prefabricated stand-up pouches or flat pouches, prefabricated special-shaped stand-up pouches or special-shaped stand-up pouches, prefabricated standard stand-up pouches, prefabricated flat pouches or stand-up pouches with zipper function, prefabricated flat pouches or stand-up pouches with straight suction nozzles , or product packaging in prefabricated flat bags or stand-up bags with oblique nozzles.

Special instructions: according to the needs of users, inkjet printers, imprinting codes, vacuum equipment, feeding machines, post-packing cartoning machines, palletizing and depalletizing, vacuum feeding machines, bucket elevators, and dust collectors can be used together. , mixer and other equipment to form an operation line product Learn about prefabricated bag packaging machine / bag feeder horizontal film packaging machine, horizontal stand-up pouch packaging machine, double-out equipment packaging machine supporting equipment

Shanghai Huacheng Service Principle: The product warranty period is 12 months. During the warranty period, the supplier will repair and replace the parts damaged due to quality reasons for free. If the parts are damaged outside the warranty period, only the cost will be charged for the provided accessories. , the equipment damage caused by human factors of the buyer, according to the accessories repaired or provided by the supplier are calculated

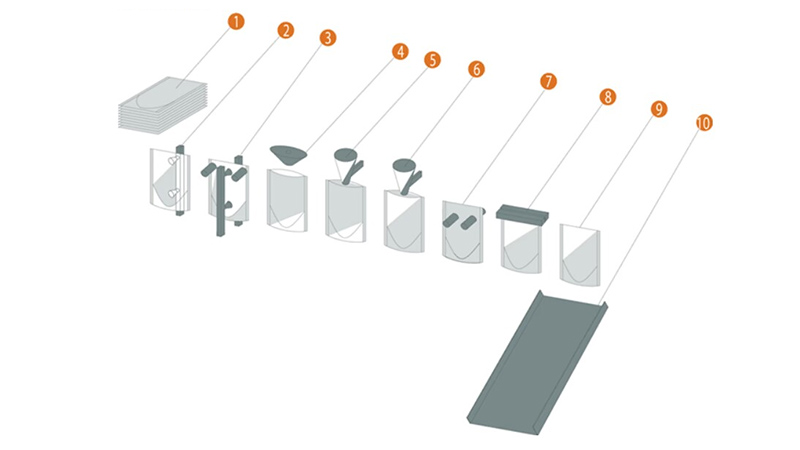

1. Stacking of prefabricated bags 2. Flip bag mechanism 3. Bag opening mechanism 4. Air blowing mechanism 5. Primary filling 6. Secondary filling 7. Bag unfolding 8. Top sealing 9. Finished product 10. Finished product output

| Model | 180NG | 210NG | 240NG | 280NG | 330NG | |

|---|---|---|---|---|---|---|

| Pouch Size(mm) | Min | 60*130 | 70*130 | 80*130 | 90*130 | 110*150 |

| Max | 180*250 | 210*300 | 240*350 | 280*400 | 330*500 | |

| Fillling Volume | ml | 1000 | 1500 | 2000 | 3000 | 4000 |

| Packaging Speed | ppm | ≤60 | ≤60 | ≤45 | ≤40 | ≤40 |

| Machine Size | mm | 2400*1100*1400 | 2550*1100*1400 | 2880*1100*1400 | 3200*1100*1500 | 3475*1215*1600 |

| Machine Weight | kg | 800 | 1200 | 1400 | 1500 | 1800 |

| Power | kw | 3.5 | 3.5 | 5.5 | 5.5 | 5.5 |

| Air Consumption | l/min | 300 | 300 | 350 | 350 | 400 |

If you are interested in HUAPACK packaging machine, please contact us via

email: info@huapackgroup.com or send your inquiry in the form below.we will reply you within 24 hours.

Privacy Policy Copyright © 2021 Shanghai Huacheng Packing Machinery Co., Ltd.